Rich With Industry Knowledge

The journey of GMSP Hi-Tech Machines began in 1945 when our late founder, Sh. Shanti Swroop ji, launched a small workshop named M/s Shanti Sheller Manufacturers. At that time, rice mills primarily operated with hullers and chakkies, which caused significant waste due to outdated equipment. Demonstrating remarkable courage and vision, Shanti Swroop ji embraced modernization by introducing simple yet effective strategies to tackle everyday challenges, setting the foundation for innovation and efficiency in rice milling.

Since its inception, we have stood for excellence and has become one of Northern Indias most respected manufacturers in the industry. Founded by the late Shanti Swroop Aggarwal, the company is now successfully managed by his grandsons Mr. Nitin Aggarwal, Mr. Bhuvesh Aggarwal, and Mr. Raghav Aggarwal who continue to uphold the legacy by focusing on standardization, meticulous planning, and high performance. Their commitment ensures that we remain a leader in delivering advanced, reliable, and efficient rice milling solutions.

The company grew from a small workshop into a large facility by 1959, beginning the manufacture of rice mills and building its own modern German rice mill, inaugurated by Sh. Raghunandan Bhatia C.P. of the D.D. Group. By 1966, it started producing complete rice mill units, though the machinery then was outdated and caused significant waste of food and oil containing materials, highlighting the need for modernization. To improve production and reduce breakage, rubber roll dehuskers replaced emery shellers in imported German setups. In 1970, the company introduced a fully Indian made rubber roll dehusker, showcasing its operation across markets in Punjab, Uttar Pradesh, Madhya Pradesh, Andhra Pradesh, and Tamil Nadu. This modernization helped hundreds of mills increase efficiency, reduce waste, and boost profits, earning the company numerous awards and recognition at industry seminars.

In 1976, inspired by Dr. Subramaniam, Head of the Paddy Processing Research Centre in Tiruvarur, M/s Shanti Sheller Makers began developing solutions to replace over one lakh rice hullers across India. Alongside manufacturing mechanized rice milling plants, the company introduced a rubber roll style micro rice machine in 1977, which was widely distributed throughout the country. Today, around 50,000 of these machines are operational nationwide. To support rice millers, the company also published a free monthly magazine, 'Achha Beopari,' with a circulation of 20,000 copies, until its production was halted during the peak of terrorism in Punjab in 1984.

After Punjab regained peace in 1995, the company revived its production facility, expanding and modernizing it beyond its previous capacity. Supported by the combined expertise of the founder, an engineer, and a highly skilled team with nearly 50 years of experience, the company continually upgrades its machinery, replacing outdated equipment with modernized mother machines. By staying attuned to evolving industry needs, the company delivers nationally recognized products that meet international quality standards, ensuring continued innovation and excellence in rice milling technology.

Our Infrastructure

Our company boasts a robust infrastructure equipped with modern machinery, advanced technology, and dedicated production units to ensure high quality manufacturing. Supported by skilled professionals and efficient processes, our facilities include research and development labs, quality control centers, and spacious warehouses. This comprehensive setup enables us to deliver innovative products with precision, reliability, and timely service, meeting diverse client requirements effectively.

Why Us?

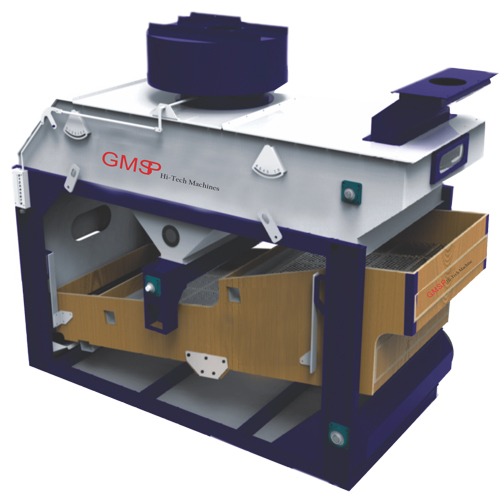

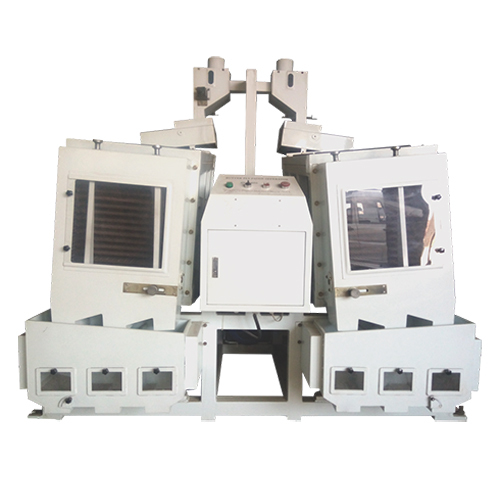

Choose us for superior rice processing solutions featuring Butterfly Paddy Separator, Rice Paddy Driers, Industrial Rice Silky Machine, Rice Precision Thickness Sizer Machine, etc. Our advanced machinery enhances efficiency, reduces labor costs, and improves rice quality with consistent polishing and grading. Built for durability and energy efficiency, our equipment ensures higher yield and cost effectiveness, empowering your milling operations to meet growing market demands with precision and reliability. Trust our expertise to deliver innovative, sustainable, and high performance rice processing technology tailored to your needs.